Click here to sign up. 131 Duration of audit man-days 6 days 2 hours 4 days hours 4 days hours 4 days.

Technical Calculation And Estimator S Man Hour Manual By Marko Bulic

For Shop welding â 1 joint per 3 meters 25 man hours for inch dia weldingâ 50 for Fitter Fabricator 25 for Welder 25 for RiggerHelper For Field welding â 1 joint per 4 meters 4 man hours for inch.

. From the example above man-hour is calculated from simple parameter. 1 025. You can substitute the values with your organizations specific value to determine the man-hour for a specific period for your organization.

1 12 029. Then estimate how many hours of labor it will take to complete each component. Man-hours estimate for piping equipment design Hagedoorn Mechanical 9 Mar 05 0619 You can use a factor for calculating the engineering work out of the total construction cost 10 and 35 for example12 till 15 for petroplant grass root revamp 25 en 35fine chemical 17 till 25 grass root.

The investigation shows that the Product Work Breakdown Structure PWBS is the best method in identifying project man-hours in Hull Shipbuilding while the man-hours comparison shows the lower W. PipingDesign and constructionHandbooks manuals etc. Cast-Iron Ductile Iron.

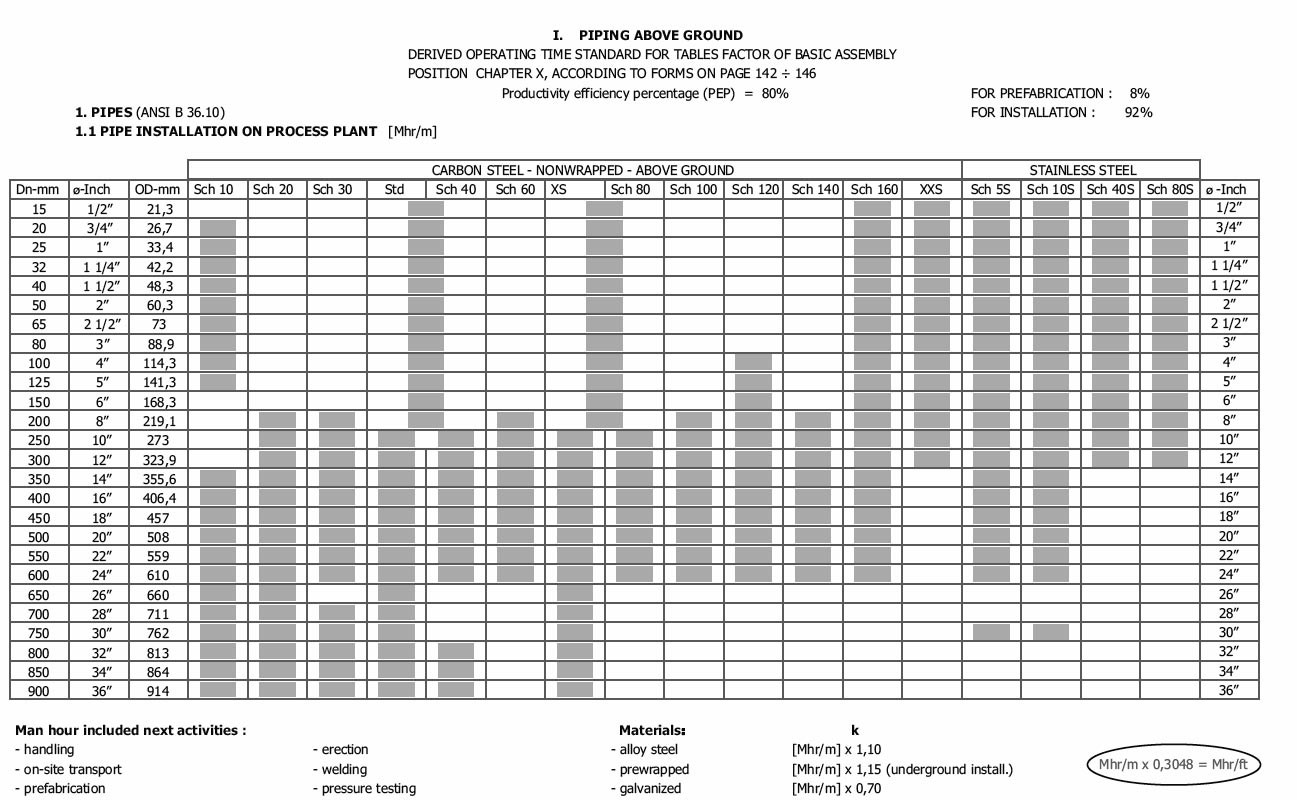

Total of design drawing man-hours. The most complex work in developing these man hours was the work on the man hours f or piping abov e ground. Remember me on this computer.

Man-hour 8 x 20 x 66 10560 hours. All total labor hours 100 remarks. 2 12 032.

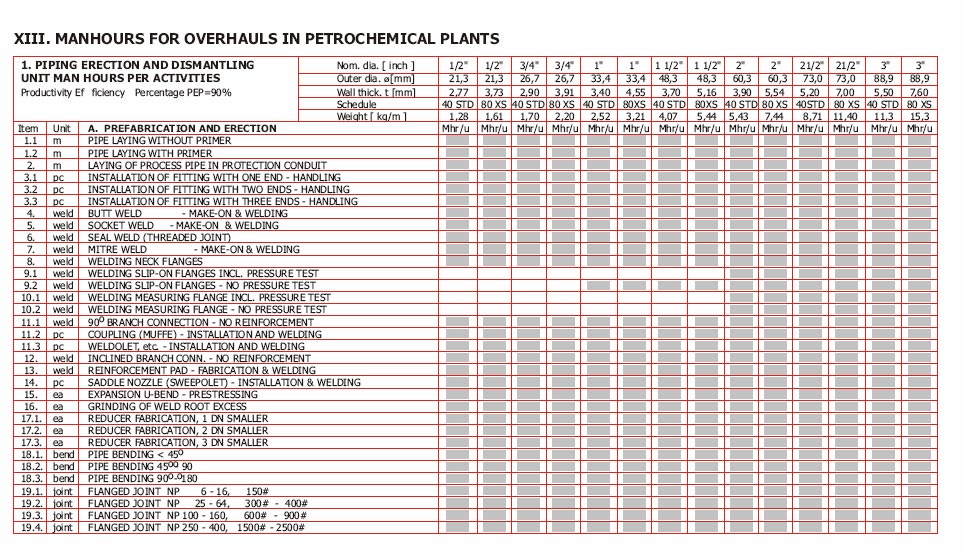

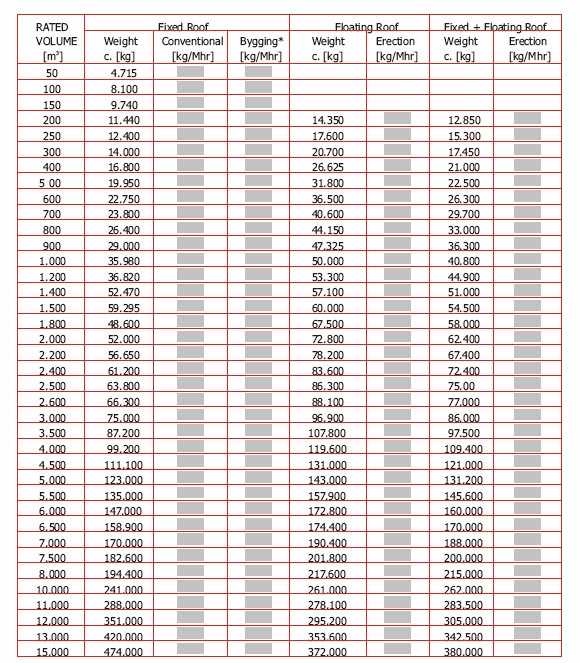

34 025. A basis I used was a system for estimating the value of erection works of a German Company LINDE which I completed and modified. Independent design drawing checking.

Piping engineering man-hour estimate design man-hours per equipment item pcoa code design manhours per. Pipe material control pipe stress engr. Tables for calculating labor in piping.

The work breakdown structure and project man-hours development will be com-pared with the latest literature review. If you want to accurately calculate time to construct a major. Hours piping design pipe material engr.

Piping and pipeline calculations manual. Typical manhours required for each of these activities are as follows. So total piping man-hours estimated would be approximately 1000 x 1212000.

To do man hour calculations for Welding Bolting Tie-in Demolition of existing lines etc etc is there any standard Norms to make the assumptions like Eg. 32 rows Piping Design Engineering involves various activities such as preparation of Plot Plans Equipment Layouts Equipment 3D Modelling Pipelines 3D Modeling Isometrics Extraction Checking. Its unique and need some self talent to define and improvement with some parameter s.

The direct man-hours stated in the 14 fourteen tables of this manual have been verified by the Author during the Piping assemblies of the different installations. Log In Sign Up. SEABEE PLANNERS AND ESTIMATORS HANDBOOK Estimating 6 working hours per day the total man hours is obtained from multiplying the following.

For the Design and Drafting of Industrial Piping Systems. Sr ActivityUnit Hours 1 Study. Pipe Sizes Man-hours.

Add for co-ordinationoverheads etc. 15 x 10 x 6 900 hours Therefore productivity is equal to 800900 089 units per hour. 1 14 029.

Hrsiso hrsiso piping engineering and design __ summary of home office labor and cost estimate final report please note only the yellow boxes are for data entry. Calculation of actual quantities from drawings. PipelinesDesign and constructionHandbooks manuals etc.

MEP Design Fee as percentage of Architects fee 10. Typical manhours required for each of these activities are as follows. F or example if the project mentioned above contains 4 stress critical lines you have to calculate critical lines from PID per stress system on an average then the total number of stress critical lines are 25041000.

Gener ally for elabor ation of the man hours f or er ectioninstallation of process equipment. MEP Design Fee 5000000 x 10 500000. Piping Stress Man-hour estimation process for a specific Project With PDF 1.

Next divide the number of hours by the number of 8-hour workdays within the amount of time you have to complete the project. 2 032. In grand total of man-hours.

Method 3 Total Staff Requirements by MEP Consultant. Estimating Man-hours for piping installation. Currently I did some observation with man-hour index.

Calculating Piping Man-hour based on Stress Critical Lines. Includes bibliographical references and index. What you should to do is more practice based on lesson learned as you have it.

16 rows Piping Stress Analysis involves various activities such as preparation of stress critical lines list modelling of lines in stress package such as CEASAR II analysis of lines marking of supports creation of stress packages and updationscreation of stress design criteria. Resource planning template excel free download how to calculate man hours. To calculate man-hours start by dividing your project into separate components like excavation construction and plumbing.

Hi Its not standardized but seems look common practice to define man-hours for design engineering. Ad Browse Discover Thousands of Home Garden Book Titles for Less. Free Estimate Templates Smartsheet.

Log in with Facebook Log in with Google. In this method the total number of. Estimators Piping Man-Hour Manual Estimators Man-Hour Library.

Man-hour is an integral factor in measuring Health and safety performance. 10162008 224 AM. Staff costs salary plus overhead Principal.

Activity Unit New Update Piping Specifications 1 Piping Layout. 12 025. Estimating 6 working hours per day the total man hours is obtained from multiplying the following.

Estimating Piping Man-hour based on Stress Packages. Wan Abd Rahman ABOUT THE AUTHORS. Construction design fabrication and examinationPhillip Ellenberger.

Enter the email address you signed up with and well email you a reset link. Close Log In. Normal practice is to estimate the number of stress packages.

FREE shipping on qualifying offers. The man-hours required to perform a task include actual working time and normal non-contributory time. As we know with the cost of man-hours it is easy to calculate how the labor force contributes to the unit cost and the profitability of the product line.

Therefore productivity is equal to 800900 089 units per hour. 15 x 10 x 6 900 hours. 3 035.

How do you calculate man-hours for piping. 3D Model Review Piping Layouts etc. Piping Estimators ManHours Manual PDF.

Engineer Construction Estimate Of Man Hours For Piping Welding Performance Of Welders Infografia Of Ebook Estimator S Piping Man Hours Tool

Technical Calculation And Estimator S Man Hour Manual By Marko Bulic

Engineer Construction Estimate Of Man Hours For Piping Welding Performance Of Welders Infografia Of Ebook Estimator S Piping Man Hours Tool

Buy Piping Man Hour Calculation For Piping Book Online At Low Prices In India Piping Man Hour Calculation For Piping Reviews Ratings Amazon In

Piping Stress Man Hour Estimation Process For A Specific Project With Pdf What Is Piping

Technical Calculation And Estimator S Man Hour Manual By Marko Bulic

0 comments

Post a Comment